Exhaust systems

The basis of our business is the manufacture and installation of sports exhaust systems made of classic stainless steel. We are a manufacturer of exhaust systems for both companies dealing with mechanical, stylistic, electronic tuning as well as for individual clients.

Our suppressors, catalytic converters, exhaust systems are offered by well-known and recognized companies such as VTG, CAR GT, Grabowski Motorsport Chojnacki Motor System Supervisor, ATC Rak system, Car Tuning, Robert Olszowka, Carzone Specials, ProjectXs, Japan Sports Service , Evergreen, and many others. Among individual recipients a huge part are the customers who want to improve the performance of their cars, have plans to modify or change the engine - a thorough rebuilding of the exhaust system is almost a necessity for it to work properly. (As an example we will use here the fact that a software change so-called "chip" in a turbocharged engine can improve the car`s performance for example, by approximately 30%. More power comes from the higher dose of the fuel / air, which can be more graphically compared with the replacement of the engine for a more powerful one ...) The problem of malfunction occurs at this point due to a too "narrow" exhaust for a stronger / larger engine - the capacity is too small, the pipes are too thin, too much back pressure forces a client to visit us.

Another huge part of our individual clients are "normal", "ordinary" users of "atypical" cars wishing to simply replace the old corroding exhaust system, but for which there is, unfortunately, no offer of cheaper substitutes (makes such as Porsche, Ferrari, Jaguar, Maseratti, Simca , and the strongest versions of the cars such as the Megane 2.0 16V, Uno Turbo Espace 3.0 V6, Passat / Golf Synchro, and many others.) The prices of original exhaust systems for these makes are, unfortunately, very high.

In constructing our exhaust systems we practice the rule of wise reduction of the back pressure through the use of suppressors of looser structure based on a flow-chamber system, or just the flow one, but based on a specific, large number of suppressor junction boxes. Large capacity combined with the best in the world market for non-woven fabric sound-proofing will "capture" only the sound wave of the exhaust and mute it so that the looser flow structure does not lose anything with the capacity of suppressors and mute them to the desired level for daily driving. Used for the construction of our special woven suppressors can withstand temperatures over 900 degrees and still be in one piece, so it neither burns out under the influence of the hot temperature inside the exhaust system, nor is it blown out through the holes in the diffusers inside the suppressors under the influence of high pressure gas flow. This ensures constant, reliable work for years without refilling suppressors with it.

In this way, we create the ideal exhaust systems that can successfully be used also for everyday use. Their sports qualities are based on their large capacity, and as far as sound is concerned - they create music that is delicate to the ear, are not troublesome during the tour of the city, not a problem during maintenance procedures.

We build exhaust systems on the basis of professional equipment and machinery, creating world-class products, fully satisfying the most demanding customers.

One such machine is the computer-programmed (by the professional ERCOLINA company) bending machine, which is able to bend resistant stainless pipes with diameters of 50.8 mm (2cale), 63.5 mm (2.5 inches) and 76.1 mm (3 inches) up to an angle of 180 degrees, without wrinkles, without throats - all the time maintaining the full diameter of the pipe.

Using a professional-bender, we can perform even the most complicated pipe connections between the suppressors in the exhaust system, which bent - not welded with the finished "bends" - form a whole in the exhaust system without being exposed to the cracking of welds in the difference in temperature, stress or mechanical damage.

Our bender works in the following way:

Our exhaust systems can be divided into two groups:

1. Exhaust systems dedicated to naturally aspirated engines:

Exhaust systems tailored to naturally aspirated engines- typically are based on the construction of two (or three) suppressors: the middle suppressor

based on the passage system, and the construction of the passage - chamber construction, working on delicate back pressure. We recommend the diameters of the barrel to be gently increased, but within reason, depending on the degree of modification of about 10-15%. Everything, of course, designed in a reasonable way so as not to loosen the exhaust pipe too much, which could have a negative effect rather than the intended one. The suppressors have a specific , large capacity, inside they are filled with a special non-woven suppressing material that was created so that it would absorb the noise in looser construction - in the low and medium frequencies. Then the exhaust system will work quietly and it will be useful not only on the track.

2. Dedicated exhaust systems for turbocharged engines:

Exhaust systems suited to turbocharged engines are a completely different structure. They are integrated to build a more complete cruising and considerably enlarge the diameter of the passage, the most reduced back pressure and maximize discharge capacity. In this type of exhaust systems muting the engine can only be based on the interception of sound, so the size of suppressors and the materials used are of enormous significance. By creating such an exhaust system - based on the construction of two passage suppressors, we create such a well suited exhaust system that during a ride all you hear is the gentle bass sound, never disruptive to the driver or passengers, revived only upon full throttle at higher engine speeds, when the exhaust flow in the exhaust pipe is big enough that the barrel construction is not able physically to completely absorb the sound wave.

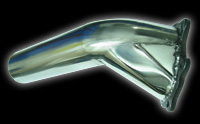

The most common turbocharged engines with a capacity of 1.8-2.0 liters with a diameter of 48-50mm (the so-called 2 inches) we recommend to increase the diameter of the passage to 63 mm (2.5 inches) with further increase of the initial part of the exhaust system to 76 mm (the so-called 3 -- DOWNPIPE inch, up-pipe). Enlarged diameter of the entry point of the exhaust right after the turbocharger is to start the rotor faster, faster increase of turbocharger rotation which results in an additional increment of power and a smaller so-called "turbolag". Some of the standard turbochargers (Subaru Impreza, Legacy, Forster, Nissan 200SX, Toyota Supra) have a pre-narrowed turbocharger exit. In narrowed exit the main exhaust impetus coming out of the turbocharger interferes with the rush of exhaust from a valve bypassing the turbocharger, the so-called waste gate. On the occasion of the exhaust system tuning, it is a very good idea to improve the exhaust emissions at this time through the use of so-called "wide collar" and a smooth transition at about 20 cm in diameter to the normal exhaust system. In this way, the main course with an additional circulation of exhaust will not interfere with the turbocharger, which will be much faster in rotation as a result of the smaller "turbolag" and greater engine power and performance.

Some of the standard turbochargers (Subaru Impreza, Legacy, Forster, Nissan 200SX, Toyota Supra) have a pre-narrowed turbocharger exit. In narrowed exit the main exhaust impetus coming out of the turbocharger interferes with the rush of exhaust from a valve bypassing the turbocharger, the so-called waste gate. On the occasion of the exhaust system tuning, it is a very good idea to improve the exhaust emissions at this time through the use of so-called "wide collar" and a smooth transition at about 20 cm in diameter to the normal exhaust system. In this way, the main course with an additional circulation of exhaust will not interfere with the turbocharger, which will be much faster in rotation as a result of the smaller "turbolag" and greater engine power and performance.

Between the two groups of exhaust types I would also place exhaust systems for V-tec engines. These exhaust systems are a compromise between maximum relaxed exhaust for "turbo" engines, which is used very well at high rpm at the time of start of the V-tec, but still gently "holding" capacity "in check" to ensure that the flexible start with naturally aspired engine speed when the V-tec is not yet turned on. In these cars we use an exhaust system usually based on two suppressors with increased diameters, but not as large as in the case of turbo engines. Suppressor junction boxes themselves should also have a large capacity so that the sound wave generated by a loud engine was "captured" to the maximum extent possible to ensure a pleasant experience in daily use of the car.

Average prices / Include VAT / | |

Exhaust pipe for a short car with a naturally aspired engine 1600-2000ccm (based on two suppressors, the 52mm diameter of the passage, cars such as Tupua Corsa / Tigra / Audi a3/Civic, Fabia, Ibiza, Golf, Polo, etc.) | ~ 2700 zł |

The exhaust system for a longer car with a naturally aspired, engine 1600-2000ccm (based on two suppressors, the 52mm diameter of the passage, cars such as Tupua Vectra, Omega, Avensis, Accord, Bora, Skoda Octavia, Toledo, Leon, Megane, Xsara, etc.) | ~ 2900 zł |

The exhaust system for a short car with a naturally aspired engine from 2000ccm engine and turbo (based on two suppressors, diameter of the passage to 63.5 mm, cars such as Civic V-tec, Golf / A3/Leon/Ibiza 1.8 turbo and 1,9-2.0 TDI Corsa / Tigra 2.0 16V, Xsara VTS, etc.) | ~ 3300 zł |

The exhaust system for a long car with a naturally aspired engine and turbo from 2.0 (based on suppressors, diameter of the passage to 63.5 mm, cars such as Nissan 200SX Turbo, Fiat Coupe Turbo, Eclipse Turbo, Octavia / Bora / Passat, Leon / Audi A4 1.8 turbo/1.9TDI etc.) | ~ 3400 zł |

Exhaust for Subaru Impreza / Legacy / Forester (based on two suppressors, 63.5 mm diameter of the passage of the expanded turbo flange and 3-inch down-pipe. | ~ 3600 zł |

The exhaust system for cars with larger capacity, turbocharged, 76.1 mm diameter of the passage (the so-called 3 inch downpipe) system based on two passage suppressors, cars such as Toyota Supra, heavily tuned turbo 2 litre engines. | from 3900 zł |

The exhaust system for high-turbocharged 6-cylinder engine or a V8 that powers often exceed 500 hp, a system based on two passage suppressors with a diameter of 88.9 mm (3.5 inches so). | from 5500 zł |

If it is physically possible - we can also perform dual exhaust systems with the departure of the gas on both sides of the bumper as L + R, the prices depend on the type of car, engine, used tips and many other factors, the price will be agreed individually in each case. | from 4000 zł |

Price includes: dismantling the old exhaust system, the installation of a new one, if needed - inserting reinforced flexible connectors, Lambda sensors, all the suspensions, guards, etc. Upon a request of the Customers we can make an exhaust system on a single suppressor, then the price of this exhaust is correspondingly lower. | |